CA2DM-led research team develops cost effective technique for mass production of high-quality graphene

Novel method uses 50 times less solvent than conventional methods

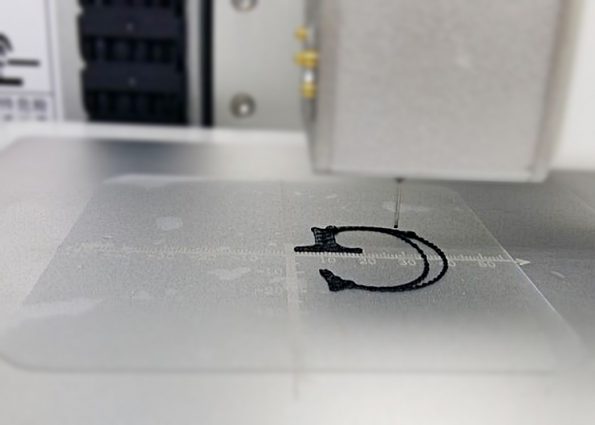

CA2DM-led research team have developed an economical and industrially viable strategy to produce graphene. The new technique addresses the long-standing challenge of an efficient process for large-scale production of graphene, and paves the way for sustainable synthesis of the material.

The difficulty to produce high-quality graphene affordably on a large scale, however, continues to pose hindrance to its widespread adoption by industries.

The conventional method of producing graphene utilises sound energy or shearing forces to exfoliate graphene layers from graphite, and then dispersing the layers in large amounts of organic solvent. As insufficient solvent causes the graphene layers to reattach themselves back into graphite, yielding one kilogram of graphene currently requires at least one tonne of organic solvent, making the method costly and environmentally unfriendly.

The CA2DM-led research team, in contrast, uses up to 50 times less solvent.

Read full news here.